This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

OUR PLASTICS

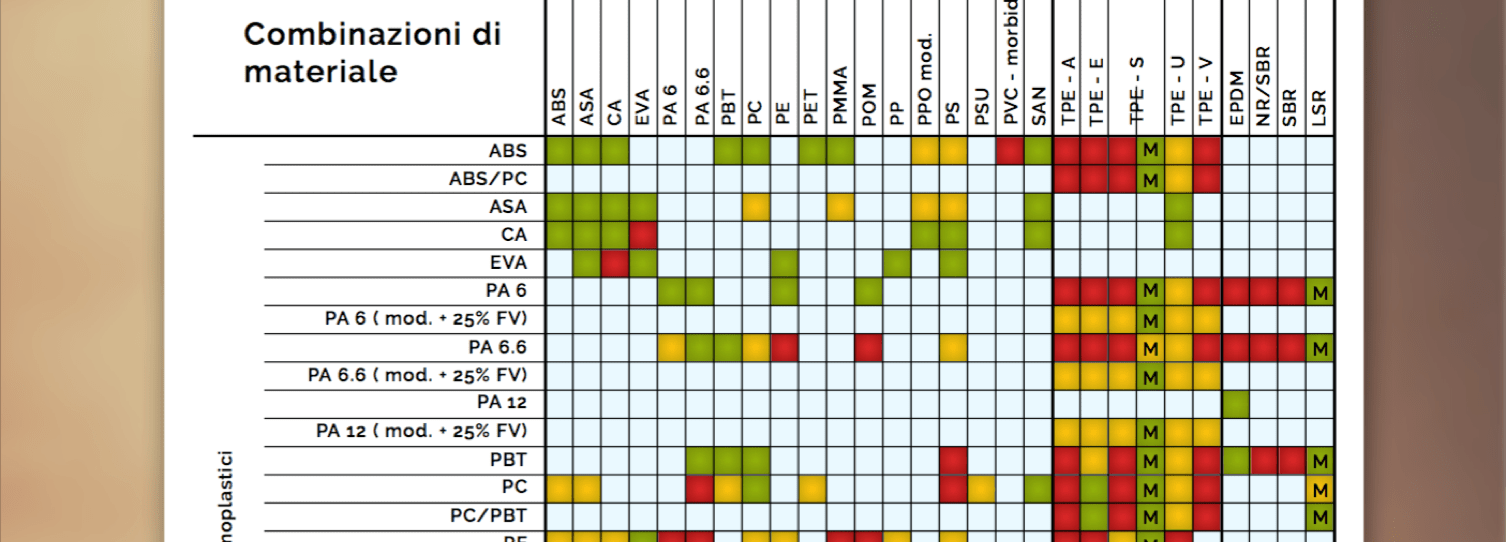

Tràfilo has a very wide range of extruded and co-extruded plastics to meet the needs of our customers.

Our knowledge of the raw materials and their intrinsic properties enables us to satisfy all the different requests of the market and to make a significant contribution to the design and development phase of our partners’ products.

Our knowledge of the raw materials and their intrinsic properties enables us to satisfy all the different requests of the market and to make a significant contribution to the design and development phase of our partners’ products.