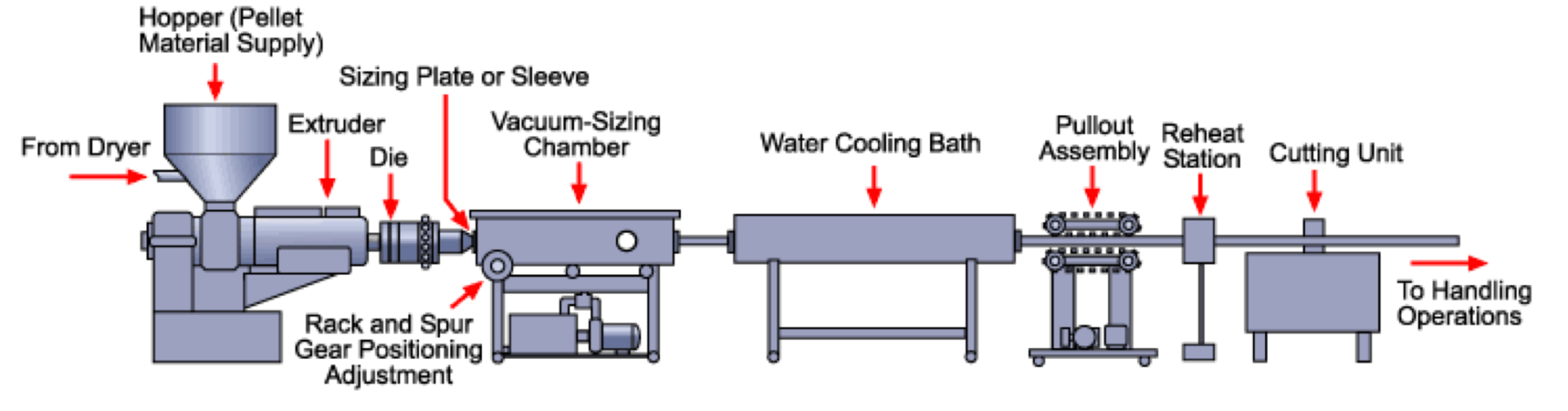

We are able to produce almost an unlimited range of products in both shape and appearance. Infact, our extrusion lines have a high hourly productive capacity but they differ according to the production types: properties and dimensions of the products.

The weight of our extruded plastic products varies from 20 g/m to 2 kg/m.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.